Industry: Manufacturing

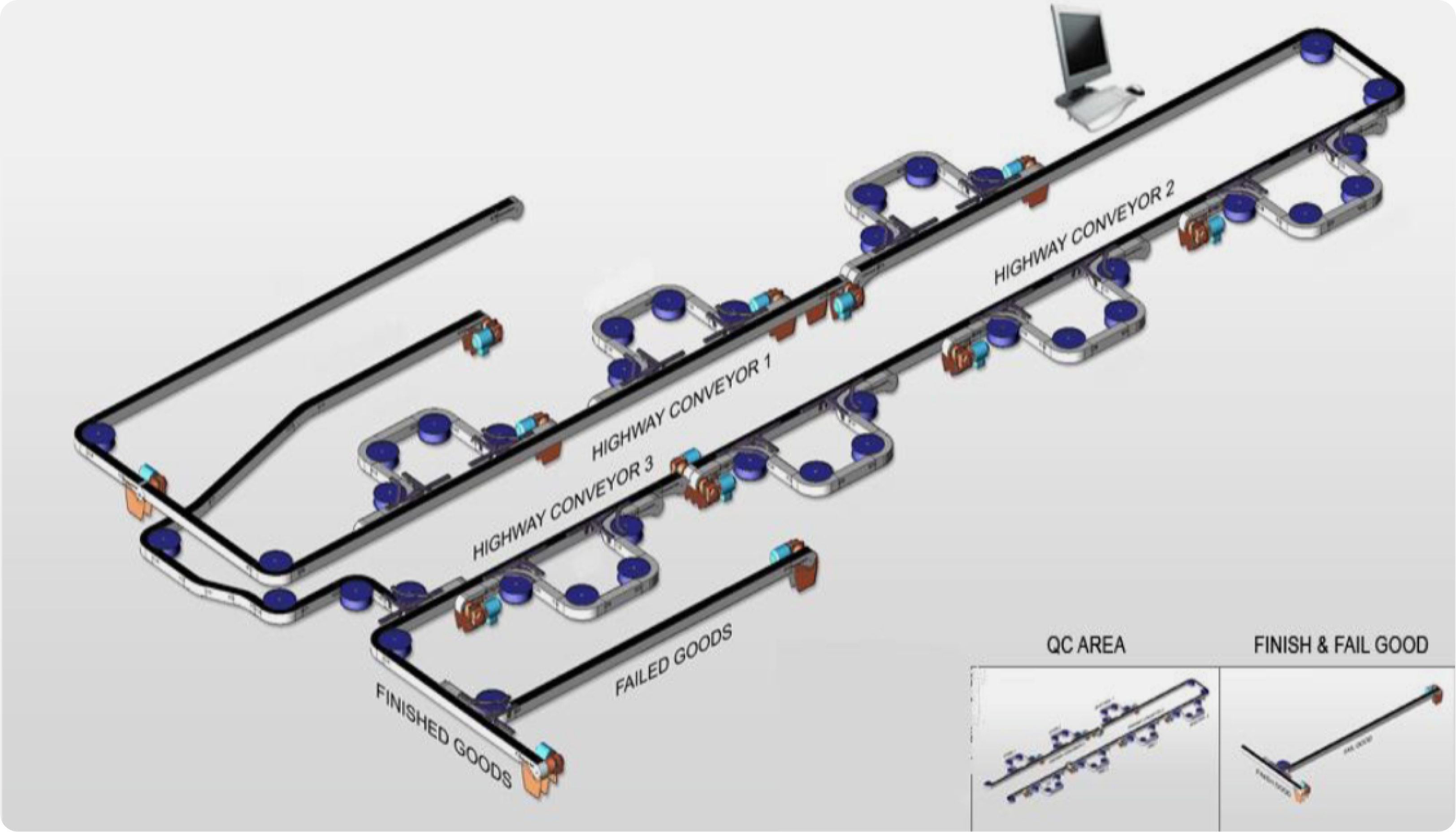

Material Handling System - Controls

Synopsis

3000 products stored and retrieved automatically thereby enabling faster and error-free dispatches with minimal man-power.

Customer Brief

This is one major fiber optic cable manufacturer. The plant manufacturers glass from the basic raw material and this is then drawn into fiber. The drawn fiber is wound on bobbins of two variants up to 50km length. Various types of machines are grouped in different sections of the plant to process the raw material to finished goods.

This is one major fiber optic cable manufacturer. The plant manufacturers glass from the basic raw material and this is then drawn into fiber. The drawn fiber is wound on bobbins of two variants up to 50km length. Various types of machines are grouped in different sections of the plant to process the raw material to finished goods.

Business situation / Challenges

The material handling system consists of quality check system and storage of the material in racks.

The final product (bobbins) undergoes 4 QC process.

The result and type of the QC that a particular final product should undergo is determined by

various factors pre-decided by software application and the results are available in the database.

Thus the routing of the final product to particular QC station is required to be automatically done. Ultimately, the finished goods are classified as ‘Reject’, ‘Rework’ and ‘Finished Goods’ and are to be segregated by the conveyor system.

The FG is to be stored in the racks and retrieved by the dispatch department automatically. 30,000 FG are to be stored and retrieved.

Complete automated system is required for both QC and Storage and Retrieval

System Components

- 40 Conveyors,

- 17 Servo drives,

- 4 Lifting stations,

- 6 Turntables,

- 5 Pick and Place robots,

- 3 Barcode readers,

- Storage and retrieval system for

- 30,000 objects

- 3000 IO’s,

The QC and Storage and Retrieval System went non-functional due to server crash &loss of Application software, HMI screens, inventory records and the interface between them

Develop new application within short period by understanding functionality of system from shop floor and management team, without affecting the production schedule

Solutions

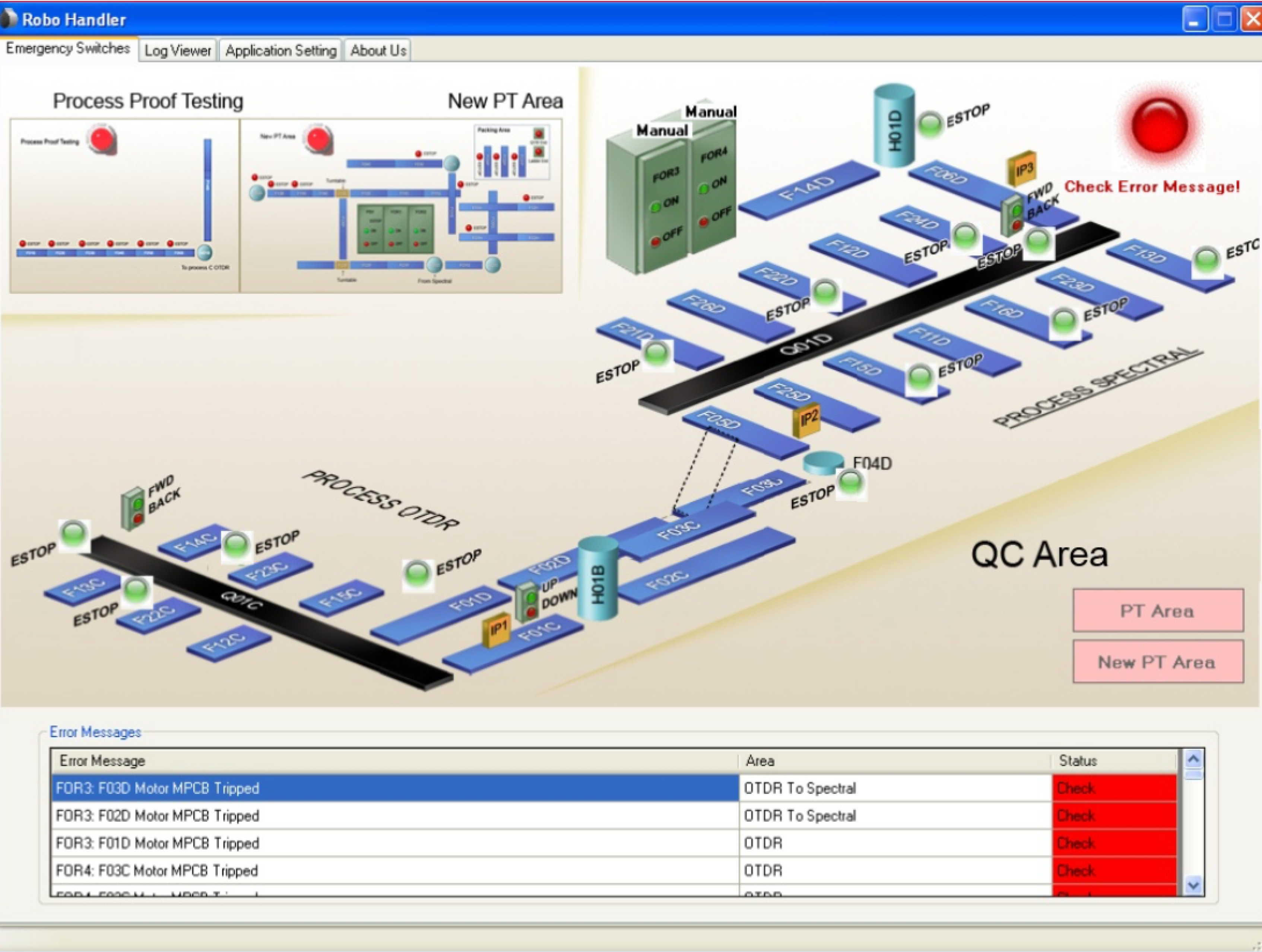

QC System

The goods produced are placed on the conveyor to transfer it to the different QC stages

The QC phase that a particular object has to be passed is updated in the database.

The object passes through the bar-code reader / RFID sensor which communicates the unique ID to the software application that integrates with the ERP.

Based on the status in the ERP, the application decides the destination of the object

Based on the results of the first QC stage, the next QC stages that a particular object has

to be passed could be decided

Finally the goods could be physically segregated as finished, Rework and Failed

Storage Retrival System

The finished goods are transferred to the storage racks designed suitably for storage and

retrieval by robot

Before the storage of a particular object, the unique ID is scanned

The object is then stored in available free space in the rack

The location of storage against the unique ID is stored in the database

The operator at the dispatch will feed the list of the unique ID’s to be delivered.

The robot will retrieve the objects from the location stored in the database and feed the goods to the delivery table/conveyor, where the goods could be packed and dispatched

Scope Brief

- Detailed understanding of the functional requirements

- Control Automation (PLC) application software design and configuration

- HMI screen development

- Interface between PLC, HMI and MES database (Oracle) on .NET platform

- Integrated test

- Commissioning

Highlights: Challenges

- No program backup available

- Documentation in German language

- 24x7 manufacturing; No shutdown time available

- Rigorous operator interviews to back build the execution logic

- ‘Prototyping Approach’ for testing and implementation

- Completed and handed over the system before schedule

Highlights: Benefits

- Automated System, Software Development and integration with mechanical system – All under one roof

- User friendly application and operator interface for operating and troubleshooting the system

- Reduction in efforts in troubleshooting the system errors

- Reduction in efforts in managing the system (time and labor)

- One controller uses with four different PLC runtimes to parallel control four different processes/areas. Thus using the strength of the control system to the fullest and optimizing the cost

- Customized Software developed to integrate the automation and ERP system

Products & services used

- Beckhoff controller and remote IO system. The communication between controller and IOs being Profibus and EtherCat in two different cases

- Human Machine Interface (HMI) – Screens developed on .NET platform

- Interface application - Developed on .NET platform. This integrates the PLC application, other software applications and ERP database (Oracle)

- Database – Oracle, MySQL

Conclusion

Proved capability of Concord in executing complex Robotics control and MES software projects

Preferred vendor for new enquiries for conveyors, robotic and complex automation applications involving IT systems.

“We are highly satisfied with Concord Technologies’ AMC services for our lighting system at JWC. Their prompt support, proactive maintenance, and system reliability have enhanced event experiences and energy efficiency. We confidently recommend their services for top-tier lighting management.”

Lutron GL Sales

JWC AMC